An Unbiased View of Masterbatch

Wiki Article

The Ultimate Guide To Masterbatch

Table of ContentsLittle Known Facts About Masterbatch.Fascination About MasterbatchEverything about MasterbatchEverything about MasterbatchMasterbatch - An Overview3 Easy Facts About Masterbatch Explained

With the goal of frothing a plastic (polycarbonate, thermoset or elastomer), include blowing solids, vaporizing them by activity of the heat provided. In concept, any kind of plastic might froth, but they are couple of, in practice, which are used in kind foamed (cell structure). Foams are those products that have cells (open, closed, or both) on all its mass and also which have a thickness lower than the material that functions as a structure (HUBBUB 7726).Stay upgraded with the current chemical industry patterns and also advancements.

Black Masterbatch is utilized to make black pigmentation for plastic products (masterbatch). It does not only aid to improve the residential or commercial properties of the ended up product as pointed out over but it also maintains manufacturing costs down for plastic makers. The black masterbatches are made use of not only for application in coloration of plastics, but also the effect reliable buildings as light security or conductivity.

The Main Principles Of Masterbatch

On top of that, a remarkable focus blend of ingredients or pigments creates the perfect selection of tinting raw polymers economically.

If the Titanium dioxide does not appropriately spread in plastics then it will bring about unefficient use pigment and a loss of optical and also mechanical homes. M. G. Polyblends White master sets are distinct in their way in that they have speciality additives that makes the resin compatible with titanium pigment as well as likewise mkaes the material to flow to make sure that it obtains distributed appropriately.

We have in our documents every little detail of the masterbatch make-up and processing problems and also thus we have the ability to replicate the exact same masterbatch at anytime in furture with no discrepancy in colour shades or various other buildings. M. G. Polyblends colour masterbatches are produced with virgin raw products and refined on the latest machinery offering excellent quality products.

Masterbatch - Questions

These masterbatches consists of unique pearl pigments having differing bit dimensions to offer luster/sparkle effect. These can be produced in silver, gold or any various other colour. These are mostly used in Injection moulded items, Cosmetic tubes and so on. These masterbatches consists of fluorescent pigments which are not just have the colour it shows however likewise produces fluorescent light in exact same colour.It provides lubricity, decreases coefficient of rubbing and also enhances abrasion resistance. It is primarily used in HDPE optical fiber ducts. It is based on amide additive which migrates to the surface area of the extruded/moulded plastic product and provide a monomolecular layer which reduces coefficient of friction (C.O.F.) between the layers of the movie as well as other surface areas which are in call with movie.

From the raw material phase onwards, till the masterbatch is lastly all set for distribution, a host of high quality checks as well as tests are performed in between. New generation systems are made use of to make sure that every analysis is reputable as well as basics accurate (masterbatch). For example, the base resin's thaw flow index is inspected utilizing the MFI tester.

All About Masterbatch

As soon as a masterbatch is established, as well as before it is launched to the customer, it undergoes numerous field tests. 2 roll mills, compression moulding machine and a lab kneader-extruder-pelletizer line are several of the tools made use of to match the masterbatch with the sample supplied by the consumer within no time at all at all.A shot moulding equipment is made use of to create examination example chips from a new masterbatch - to the same specs that the client would employ in real application. Such prototyping is the end result of the complicated and also requiring process of developing a special as well as perfect solution. It is also the ultimate examination of the top quality and also performance of the masterbatch - an index of whether it will really deliver what it assures.

Some Known Facts About Masterbatch.

G. customer. Should he call for a repeat consignment of a certain masterbatch also years later, he will certainly get a real and best reproduction of the original.he has a good point Producers use the substantial majority of the white masterbatches in the packaging market, in applications such as food, cosmetics, cleaning agent, and commercial supplies. A premium, affordable remedy, the white masterbatches have been created to hold up against severe handling problems, consisting of extrusion, injection and blow molding, stopping pass away accumulation, hefty smoke and strong odor that can be triggered by high processing temperatures.

We recommend you can trial examination with 2 ideal terrific as well as. For additional information and also the requirements, please call us via .

Masterbatch Fundamentals Explained

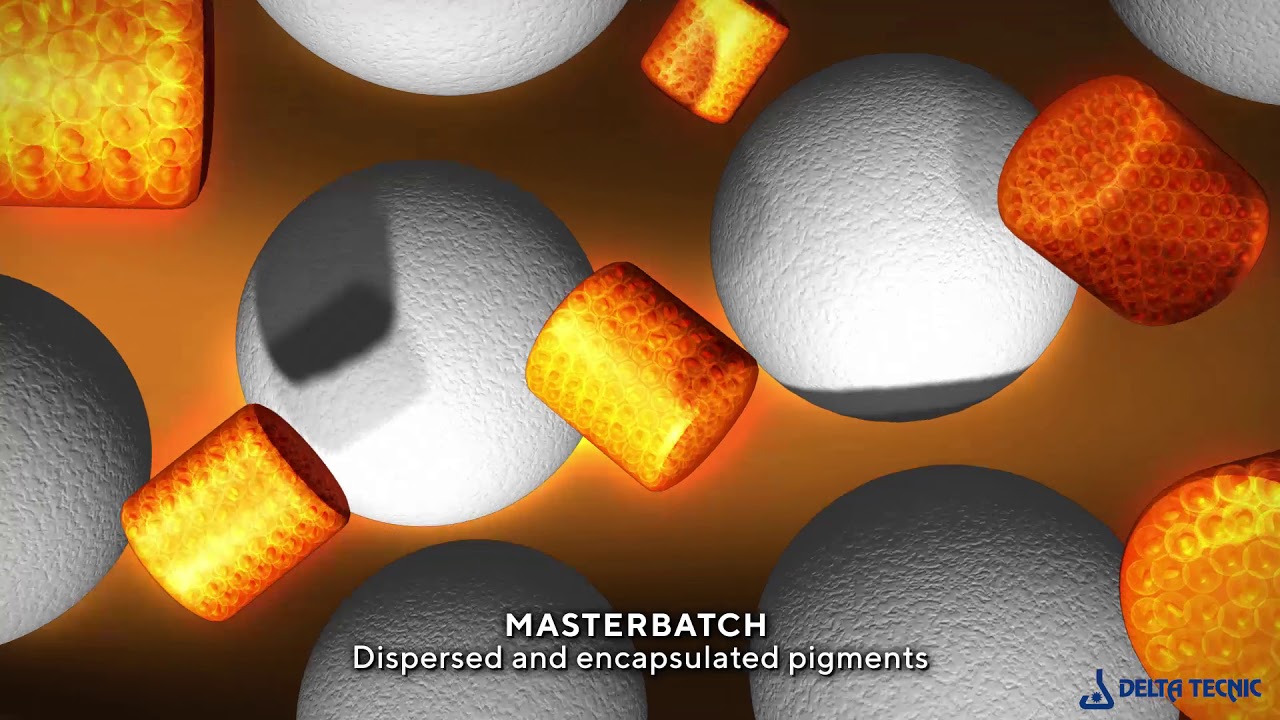

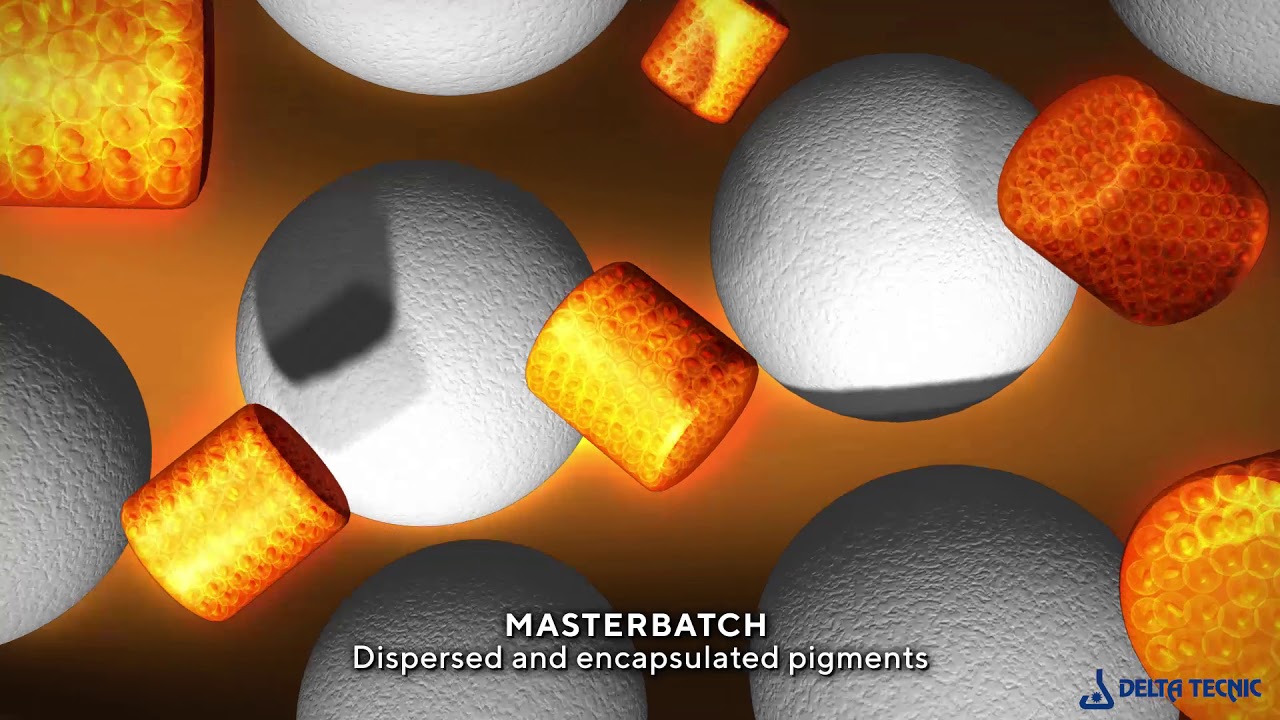

Shade, Combi or Additive Masterbatches (including) with strong or liquid service providers intend to shade (tinted masterbatches) or to provide various other residential properties (additive masterbatches) to plastics. Masterbatch is a concentrated mixture of pigments and also/ or additives encapsulated throughout a heating procedure in a service provider resin that is cooled down as well as reduced right into a granular form.

Since of the conflict of the fluoropolymers with the plastics and the high fondness for the steel, a thin covering is developed in the extruder pass away. The friction between the molten plastic and also the metal die-wall decreases, resulting in a minimized stress on the plastic. This gets rid of the thaw fracture throughout the extrusion of (m)LLDPE abundant blends at high shear rates (outcome prices).

Report this wiki page